In the dynamic realm of manufacturing, a stark disparity often exists between the cutting-edge technology embraced in personal lives and the traditional, sometimes antiquated, systems prevalent within industrial settings. A vivid illustration of this incongruity emerges when stepping into a plant manager's office – an arena where the gleaming pride in remotely starting a Tesla and brandishing the latest iPhone coexists with a landscape of paper and outdated machinery.

Gilad Langer, the Industry Practice Lead at Tulip, aptly encapsulated this paradox during our enlightening Operations Calling™ conference. The stark contrast between the avant-garde gadgets discussed in managerial offices and the tangible reality of manufacturing floors highlights a persistent technological lag.

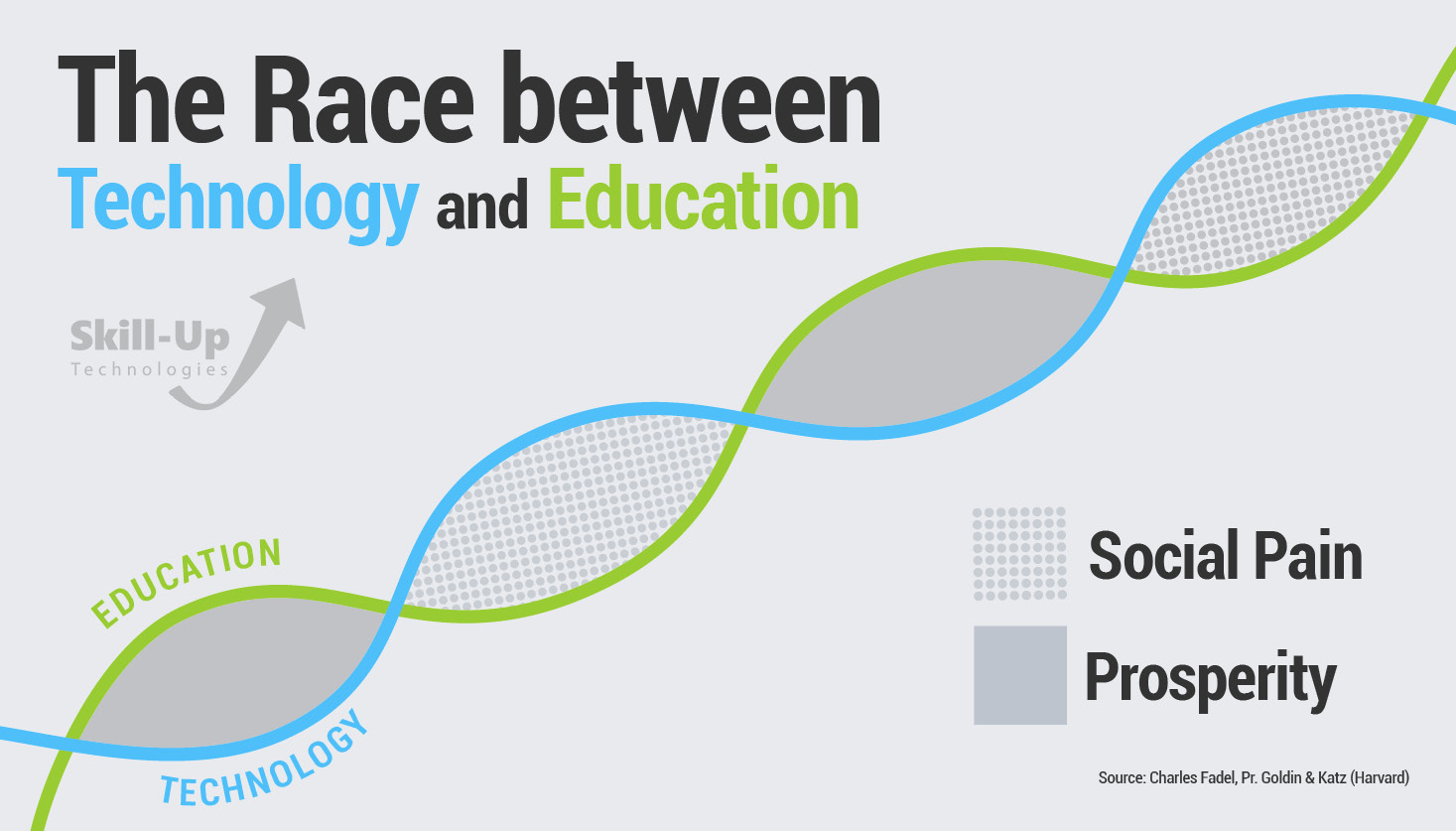

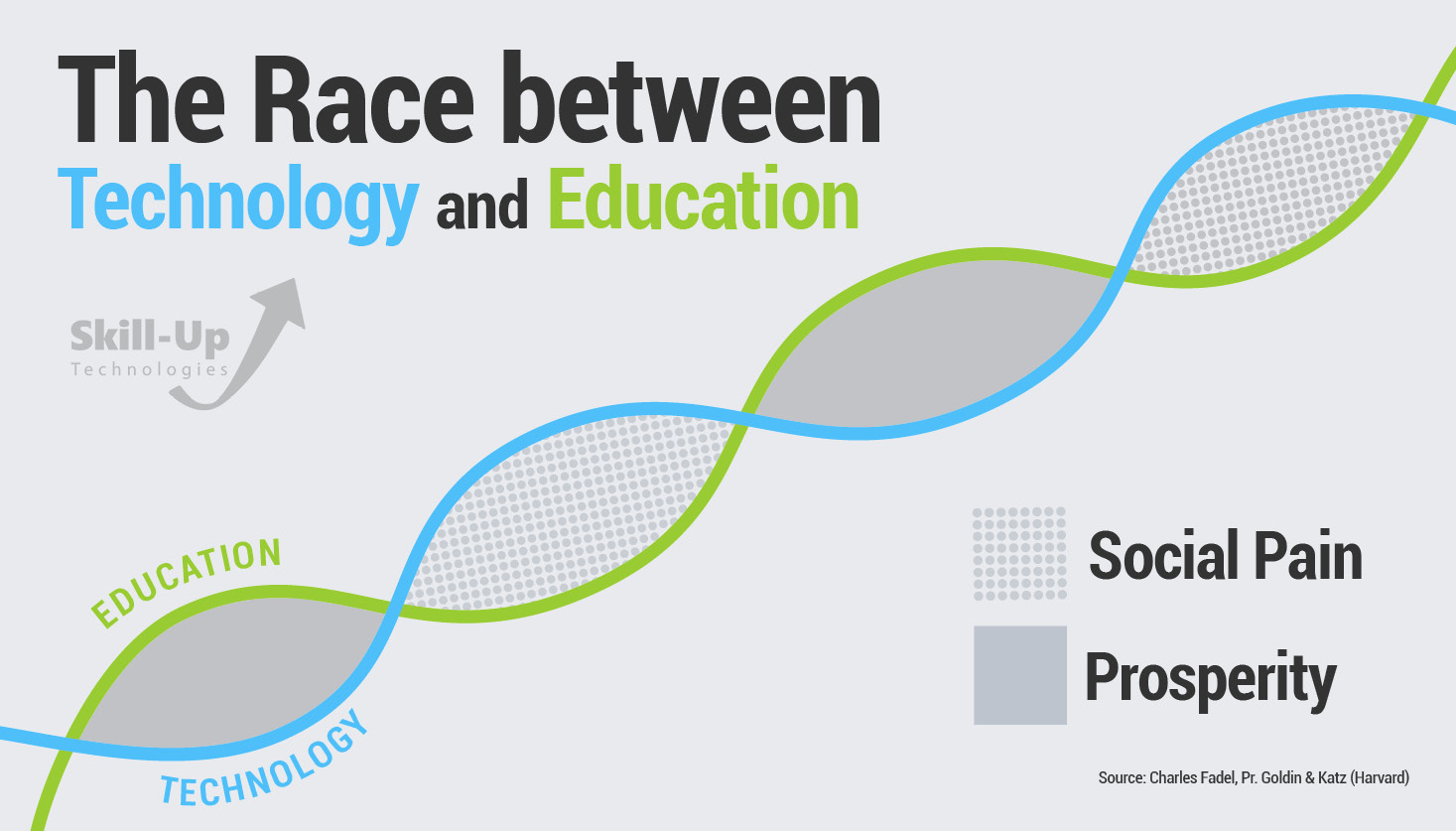

A mere decade ago, the internet underwent a transformation so profound that its previous iteration seems almost unrecognizable. Yet, juxtapose this rapid evolution with the comparatively sluggish advancement of manufacturing operations technology, and a glaring incongruence surfaces. The manufacturing sector stands at the crossroads of a digital revolution, where the pace of technological growth in personal spheres far outstrips the metamorphosis witnessed within industrial operations.

As we navigate this era of accelerated technological progress, it becomes imperative for manufacturing professionals to bridge this gap. Embracing the potential of Industry 4.0 is not merely an option but a necessity for thriving in a landscape where innovation is the heartbeat of success. The dichotomy between the modernity of personal technology and the inertia within manufacturing operations serves as a clarion call for industry leaders to spearhead a paradigm shift.

The contemporary manufacturing ecosystem demands an integration of smart technologies, data analytics, and automation to usher in an era of efficiency, sustainability, and competitiveness. Initiatives like remote monitoring, predictive maintenance, and real-time analytics are not just buzzwords but transformative tools that can reshape the narrative of manufacturing excellence.

As we celebrate the one-year milestone of this technological journey, it's opportune to reflect on the imperative for manufacturing to keep pace with the relentless march of innovation. The internet's evolution over the past decade serves as a poignant reminder – adaptability is the cornerstone of relevance.

In essence, the juxtaposition of personal and professional tech landscapes in manufacturing underscores the urgency for a holistic digital transformation. The disconnect witnessed today can be the catalyst for a future where plant floors resonate with the same vibrancy as a technologically advanced office. The journey towards harmonizing these realms is not just a technological evolution; it's a narrative of resilience, adaptability, and the unwavering pursuit of progress.